Being in Teesside, we’re fortunate to be able to take advantage of the existing engineering skill set and the established supply chains and supporting infrastructure, thanks to the petrochemical, chemical and pharmaceutical businesses nearby.

Dai Hayward, Micropore Technologies

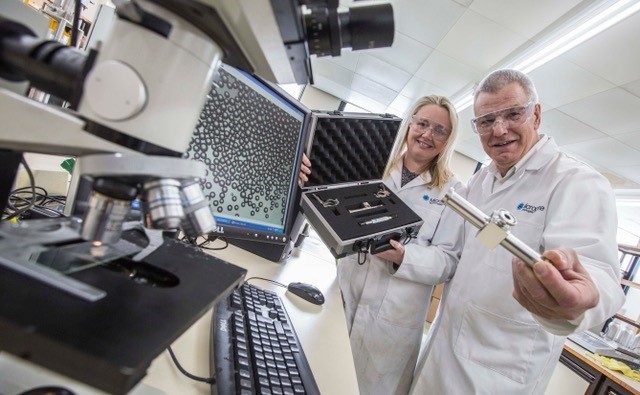

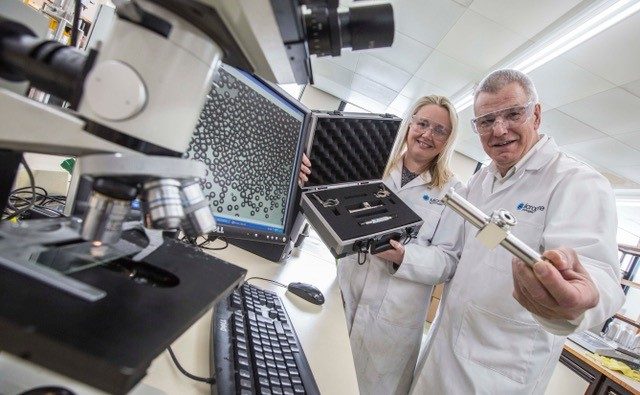

Micropore Technologies was founded in 2003 as a spin-out company from Loughborough University and, when Dai Hayward joined as CEO in 2010, one of his first steps was to pursue independence by moving to ‘new’ offices and lab space. Dai explained: “It was great to become independent, but we relocated to what can only be described as a crinkly tin shed, which was not ideal as far as our customers were concerned. When you’re a technology company trying to solve a sector-wide problem of how to scale up production of microparticles, it helps to have offices and labs that reflect the quality of your scientific research!”

So, in January 2016, the company made a move to the Wilton Centre in Teesside. Dai continued: “The fresh environment is a huge improvement on our previous premises, and our new postcode also enabled us to access funding from UK Steel Enterprise, which supports job creation in ex-steel areas. We’re a small team of five engineers and chemists, and we outsource a fair amount of our work to external contractors, while keeping quality assurance in house. Being in Teesside, we’re fortunate to be able to take advantage of the existing engineering skill set and the established supply chains and supporting infrastructure, thanks to the petrochemical, chemical and pharmaceutical businesses nearby. All in all, it makes sense to be here geographically, and we know that there will be few limitations on space and hiring quality workforce talent as we grow.”

And growth is precisely what the company is anticipating. In November 2017, the in-house team was delighted to finally crack the problem they had been working on for the past five years, leading to the development of a uniquely scalable emulsification system capable of producing up to a thousand tonnes of microparticles a year. “For the next couple of months, we will focus on marketing and sales of our new scale-up platform. It’s a breakthrough for the industry, and we’re excited that initial customers are already responding very positively. There’s still lots to do – the ideas from the team keep coming! In the meantime, we’re in discussion with investors about a significant investment that will enable Micropore to dramatically increase its market penetration in its target market sectors. It’s amazing to see how far we’ve come since the early days in the crinkly tin shed. The signs are looking positive for a high growth future and we’re very excited to see what’s in store for Micropore Technologies,” Dai concluded.

To learn more about Micropore Technologies, visit www.micropore.co.uk